How Do I Inspect My Safety Harness?

While often associated with working at height, safety harnesses are also used for work in confined spaces. When an emergency occurs, and a rescue needs to be carried out, having a fully functioning safety harness can mean the difference between life and death.

So, although inspecting your safety harness before each use may seem tedious it should become second nature. While all safety harnesses should have regular formal inspections by a competent person do you really want to trust your life to someone else?

Knowing how to perform a proper inspection and doing so prior to every use is the best way you can take your safety into your own hands. So, when inspecting your harness, what is it exactly that you need to look for?

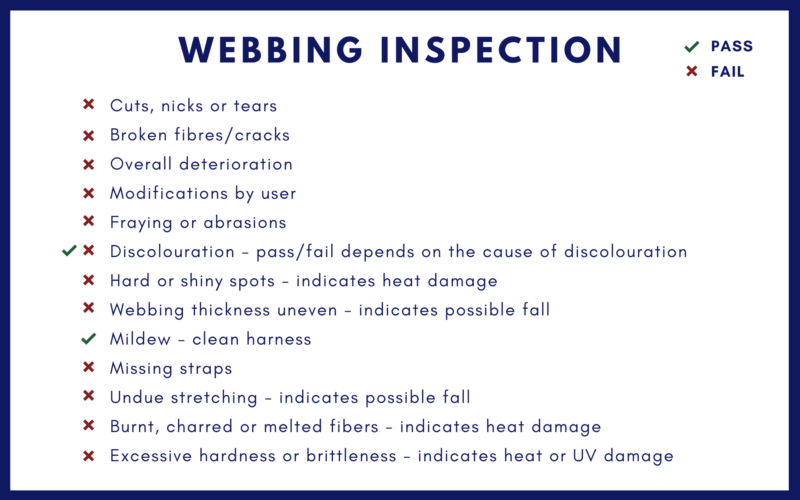

Webbing Inspection

First, untangle your harness so you can check that you aren’t missing any parts. Grabbing the harness by the back D-ring is a good place to hold it to shake it out and then holding it by the shoulder straps can help you get a good visual.

Then, check the entire length of the webbing for any cuts, tears or other damage. The material should feel flexible, but you don’t want to see any stretching, fraying, burns, melting or missing straps. If you notice any stretching or uneven thickness of the webbing this might indicate that the harness has been involved in a fall. Use the boxes below to aid your inspection and if you encounter any of the defects with a red x next to them, the harness should not be used.

Stitching Inspection

Now, check for any pulled stitches or areas where the stitches are damaged or missing. Hard/shiny spots or discolouration might be the result of heat damage and the harness should not be used.

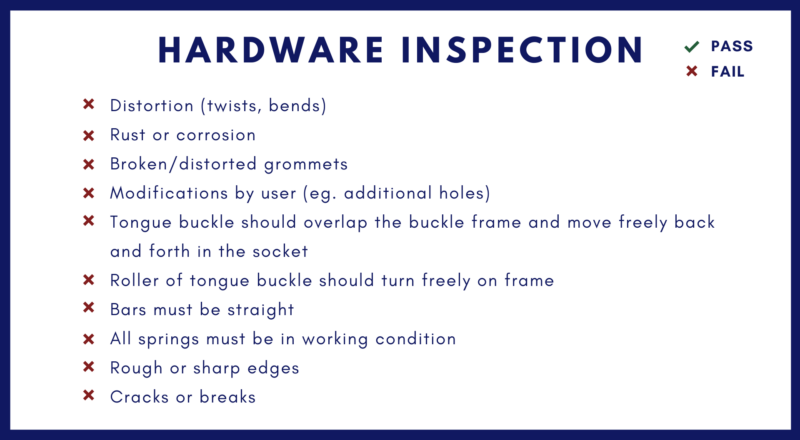

Hardware Inspection

The hardware includes all the metal buckles and grommets, as well as the plastic loops that keep the ends of the webbing in place. Check all the plastic for cracks, tears or deformities. Check the metal for bending, cracking or signs of rust and corrosion. The tongue in the buckle should line up and overlap the frame. When inspecting the grommets, you’re looking to see if one or more look more used than the others – this is a weak spot. Finally, check all the buckles to make sure they’re working properly.

Identification/Labelling

The harness should also have all the proper tags and labels. The labels must be legible and contain identification data about the harness such as model number and manufacturer. It should also state the limitations and safety warnings related to the use of the harness. If this label is missing or illegible the harness should not be used. You also need to confirm the manufacturing date is present and that the harness does not exceed its working life.

In addition, it is important to stress that if there is no test date on it or it is out of test date DO NOT USE the harness. Likewise, if there is no serial number on the harness DO NOT USE the harness. These are both essential to prove the harness is from a regulated manufacturer and has been recently checked by a competent and trained person. Your employer should have procedures in place for formal inspections every 3-6 months depending on how heavy the harness use is and these formal checks should be undertaken by a competent and trained person and a record should be kept.

Although it should be thorough, your harness inspection does not need to take a long time. The important thing to remember is that in the event of an emergency the harness could be the thing that saves your life (or not if it is damaged or faulty!).

Civil Safety Training & Rescue

We provide regular confined space and self-rescue training courses with practical elements that include training on the use of PPE such as safety harnesses. We also sell, service and hire out safety equipment and our experienced technicians can help you choose the best equipment for your work.

Training: 01480 220611 | Rescue: 01480 220615 | Service, Sales & Hire: 01480 220613