Confined Spaces: Common Hazards and Staying Safe

Each year in the UK a number of people are killed or seriously injured in confined spaces and so being aware of the common hazards and how to stay safe is vitally important. It is imperative that businesses ensure their staff not only understand what to look out for but are also able to work safely and know how to respond in dangerous situations.

A confined space is defined by HSE as:

“Any place, including any chamber, tank, vat, silo, pit, trench, pipe, sewer, flue, well or other similar space in which, by virtue of its enclosed nature, there arises a reasonably foreseeable specified risk”.

Confined spaces also have two key features. First, they are substantially (though not always entirely) enclosed. Second, there is a reasonable foreseeable risk of serious personal injury from hazardous substances or conditions within the space or around it.

The potential hazards confronting workers in confined spaces are wide and varied. The hazards listed below are some of the common ones but there are many more and comprehensive training should be carried out before working in confined spaces or supervising others.

Atmospheric Hazards

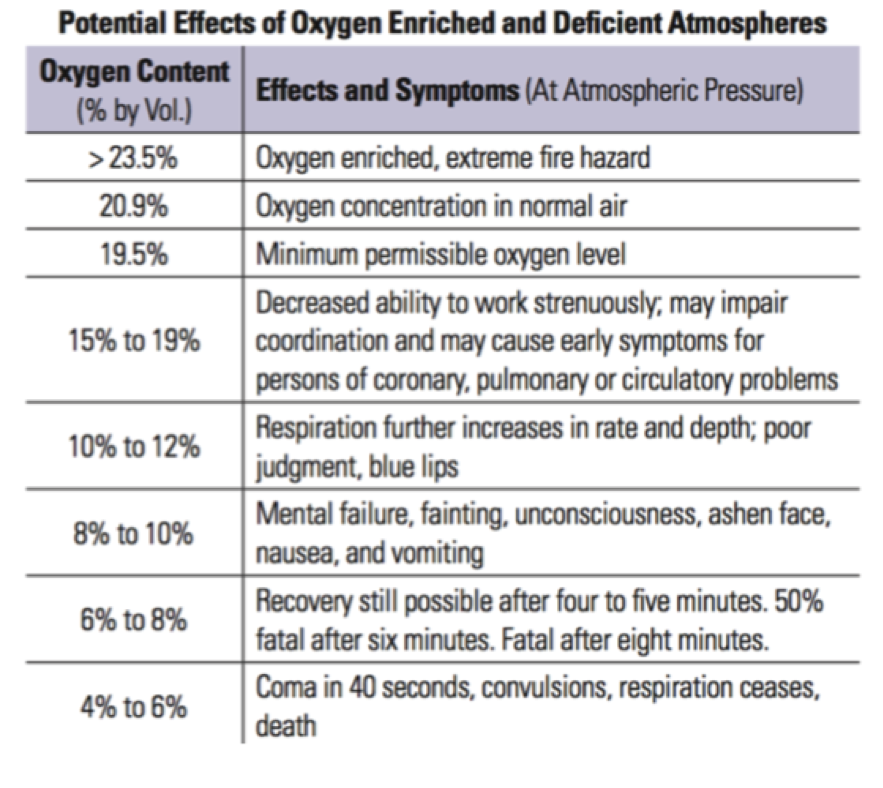

Lack of Oxygen

Oxygen deficiency in confined spaces is a hazard to be taken very seriously with most fatalities in confined spaces the result of atmospheric problems. The atmosphere is considered oxygen-deficient if there is less than 19.5% oxygen. Rusting metals and combustion, oxygen being replaced by other gases such as welding gases and micro-organisms such as those present in sewers can all lead to low oxygen levels which also means that oxygen levels can decrease while the worker’s activity is being carried out and so continuous monitoring is necessary.

Too Much Oxygen

While less common, too much oxygen – over 21% – is also a hazard to be mindful of as it increases the risk of fire or explosion, particularly if works such as welding are being carried out in the space.

Toxic Gases

Even when oxygen levels are normal there may be contaminants in the air that make it toxic. One common toxic gas is hydrogen sulfide which has a distinct smell of rotten eggs and is commonly associated with raw sewage, animal products and the pulp and paper industry. Another is carbon monoxide which is odourless and colourless and is produced as a by-product of incomplete combustion.

Checking the quality of the air both before entry and while working is critical. Before entry, the atmosphere must be tested for oxygen content, flammable gases and vapours, and toxic contaminants, in that order. When monitoring, air samples must be taken at the top, middle and bottom of the confined space as the gases and vapours will vary in concentration.

Access Hazards

Many confined spaces are difficult to get in and out of and can only be accessed using ladders or hoists. While this isn’t usually an issue in itself it becomes dangerous if someone has a medical emergency and needs to be rescued. Having a well thought out rescue plan is always a requirement when working in confined spaces but a dedicated rescue team with the appropriate training, equipment and experience should also be considered.

Engulfment Hazards

The risk of being engulfed can occur from both liquids and solid materials which can flow such as grain, sugar, flour or sand. With liquid, it can flow into the confined space and lead to drowning or, depending on the liquid itself can also be corrosive or toxic. With free-flowing solid materials in a confined space it can act like quicksand and bury a worker in seconds. There are several steps to take to ensure the entry is as safe as possible including locking out all equipment and providing workers with body harnesses attached to lifelines or winch systems.

Physical Hazards

Extreme Heat

Heat is a common hazard when working in confined spaces and is often made worse by wearing personal protective equipment. The risks include heat stroke and unconsciousness, which is very dangerous in a confined space.

Moving Parts of Equipment and Machinery

Mechanical equipment such as mixers and rotating tanks can be dangerous if activated or not secured. To ensure accumulated pressure or residual energy doesn’t pose a risk, a specific lockout procedure must be followed and tested. Even when locked out there can be other equipment that can move so this must also be secured.

Poor Visibility

Poor visibility from lack of light or activities such as sandblasting or welding increases the risk of accidents and makes it harder to see if a worker is in distress. Portable lighting (explosion-proof where necessary) and ventilation can help improve conditions.

As confined space experts we know how important it is to make sure any person working in a confined space has the right training and is aware of the potential risks and how to minimise them. Even when not entering the confined space, those managing and supervising the work but also be suitably trained to carry out their part.

Contact our team to discuss your training, rescue or equipment requirements.

Contact

Training: 01480 220 611

Rescue: 01480 220 615

Equipment Sales and Servicing: 01480 220 613